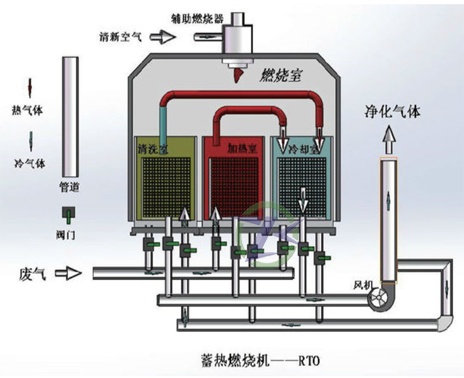

The operating principle of RTO is to establish a special thermal oxidation furnace, which can have a certain thermal storage capacity, and specially treat the organic waste gas, so that the organic waste gas can be decomposed in high temperature environment, so as to meet the relevant national environmental standards and discharge it into the air. In the process of applying RTO mode, it is necessary to set up two fixed forms of heat exchange media beds, which are made of ceramic materials with heat storage advantages, so as to carry out the treatment of organic waste gas. The organic waste gas will be heated after passing through a ceramic media bed. In the case of heat exchange, the other media bed will also be heated, and the heat exchange rate can reach 96%. At the same time, in the process of application of oxidation furnace equipment, it has certain self-sustaining ability, can maintain the problem without any fuel, improve its efficiency.

1, working principle:

The regenerative thermal incinerator combusts organic waste gas directly with natural gas, decomposes the organic molecule into CO2 and H2O at 750-850 C, and the burned flue gas accumulates heat in the ceramic by regenerative ceramic brick, preheating the organic waste gas, and then discharges it. The direction of the exhaust gas in and out is switched automatically through the switching valve to circulate. Work, RTO can fully recover the burning organic decomposition heat energy, make the system energy consumption greatly reduced.

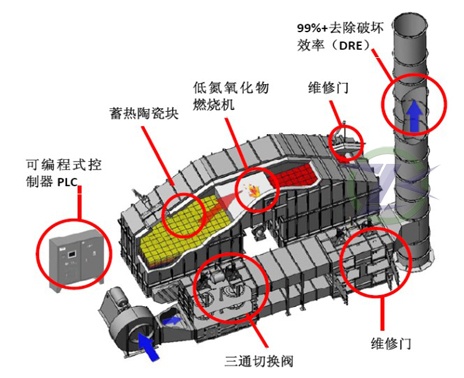

2. System composition:

The system consists of waste gas pre-treatment drying, filter, switching air valve, combustion furnace, gas system, combustion-supporting system, compressed air system, exhaust system.

Product characteristics:

1. There are many alternatives: RTO regenerative combustion equipment can have two-bed, three-bed and rotary and other optional processes;

2. Wide range of application: RTO can deal with VOCs exhaust gas of most components. Because there is no catalyst used in catalytic combustion equipment, there is no catalyst poisoning and so on.

3. High removal efficiency: the highest purification rate of exhaust gas of three-chamber RTO regenerative combustion equipment can reach over 99%, which is suitable for different working conditions.

4. Smoother operation: multiple real-time monitoring can be realized by extinguishing protection, over-temperature alarm and PLC system, which can realize the function of fault self-checking and removing, and ensure the safe operation of the equipment.

5. High economic benefit: It can be equipped with waste heat device on demand to realize full distribution and utilization of waste heat, so that the heat exchange and heat recovery efficiency of the equipment is higher, and the operation cost is greatly saved.

Applicable exhaust gas:

1. Applicable organic waste gases: hydrocarbon organic waste gases such as alkanes, olefins, alcohols, ketones, ethers, esters, aromatic hydrocarbons, benzene, etc.

2, low concentration of organic matter (at the same time below 25%LFL) and large air volume.

3, the exhaust gas contains many organic components or organic components, which often change.

4, containing exhaust gas which is easy to cause poisoning or active degradation of catalyst.

Widely used in petrochemical, medical, carbon fiber, food additives, solar energy, spraying industry and other organic waste gas industries, organic waste gas treatment, treatment efficiency as high as 95%.

- Home

- |

- Zhuoke

- |

- Products

- |

- News

- |

- Support

- |

- Project Case

- |

- Guest Book

- |

- Contact US

Dongguan headquarters: Dongguan Zhong Ya Zhuo Ke Industrial Equipment Co., Ltd.

Address: No. 4 Minchang Road, 6th Lane, Nanzha Sixth Industrial Zone, Humen Town, Dongguan City, Guangdong Province

Tel: 0769-81919829 (50 line)

Fax: 0769-81919209

Service hotline: (086)-13823757288

E-mail: wxzk@szzkgy.com

Web site: www.szzkgy.com

-

Zhuo official website

-

WeChat public number

Equipment consulting1

Equipment consulting1 Consulting phone:13823757288

Consulting phone:13823757288 QR code

QR code